Transportation

Application Overview

Plastic films play a crucial role in the transportation industry, providing innovative solutions for improved performance and efficiency. These versatile materials are used in a wide range of transportation applications, offering lightweight, durable, and visually appealing solutions.

Products Used:

Material Solutions

HDPE (High-Density Polyethylene)

LDPE (Low-Density Polyethylene)

LEXAN™

Fluoropolymers

PP (Polypropylene)

PETG

Teslin / Tyvek™

UHMW

Product Examples

Protective Films

Automotive Interior

EV Battery Insulation

EV Charging Stations

Lightweight & Durable Cargo Covers

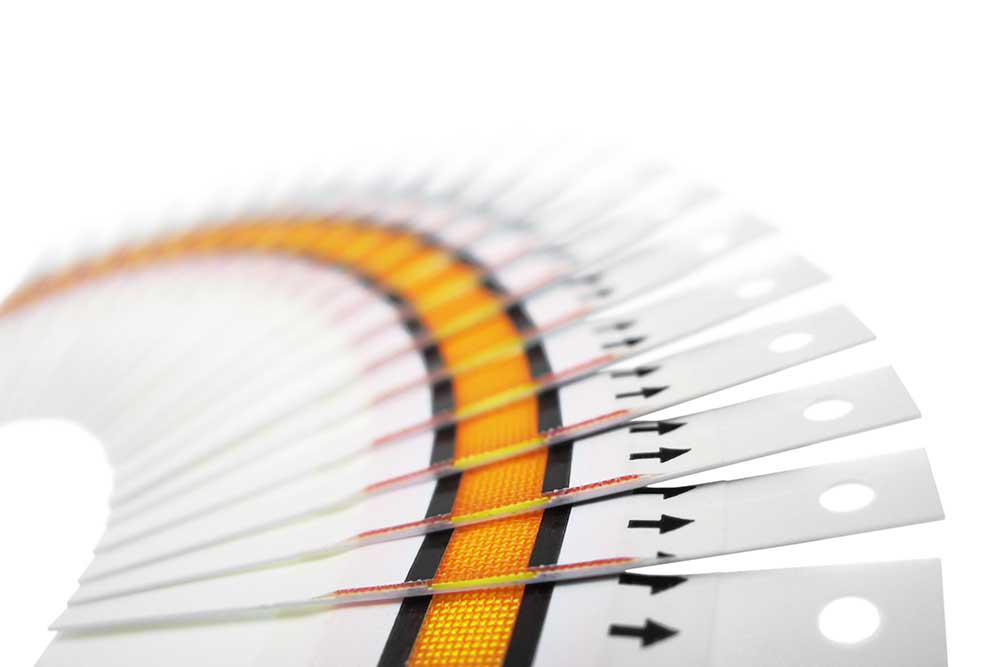

Utilizing our HDPE or LDPE films, you can ensure the protection of goods during transport. These films provide excellent tear resistance and durability, ensuring cargo is shielded from harsh weather conditions and external factors.

High-Performance Automotive Interiors

Our engineering films, LEXAN™ and Acrylic films, provide the perfect combination of aesthetics, durability, and easy formability, enhancing the interiors of vehicles while providing an appealing, high-end look.

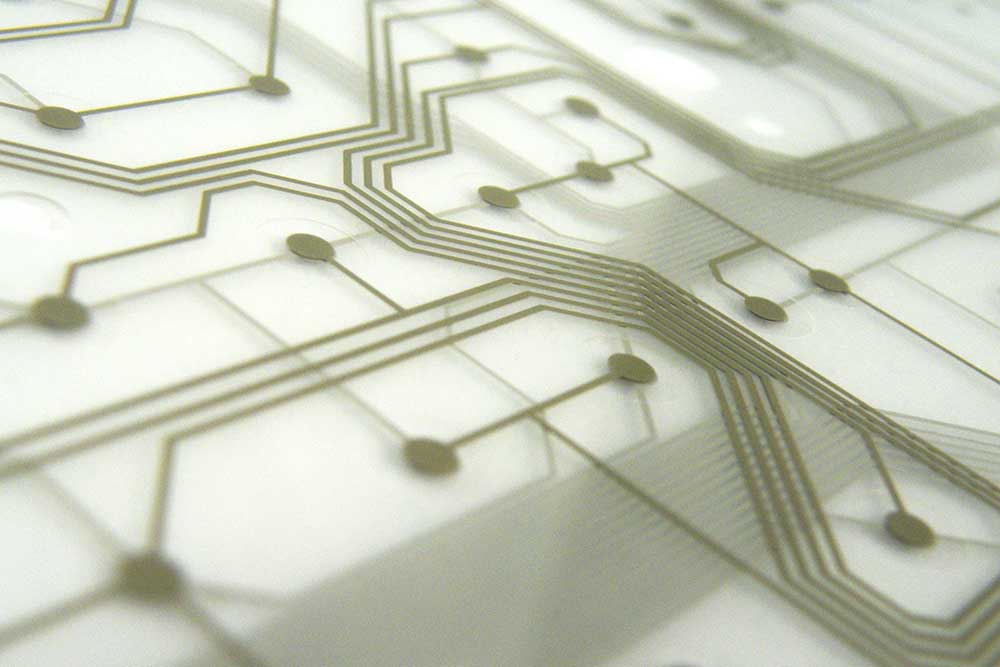

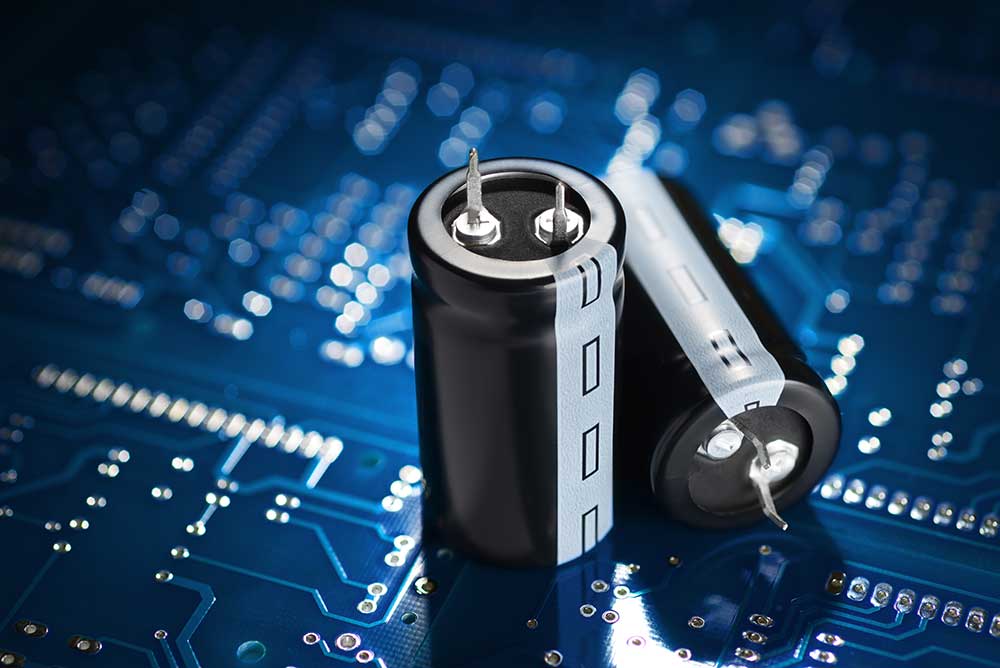

Safe & Reliable EV Battery Insulation

Use our Fluoropolymers and High-Performance Films for excellent thermal and electrical insulation in Electric Vehicle (EV) batteries, ensuring their safe and efficient operation.

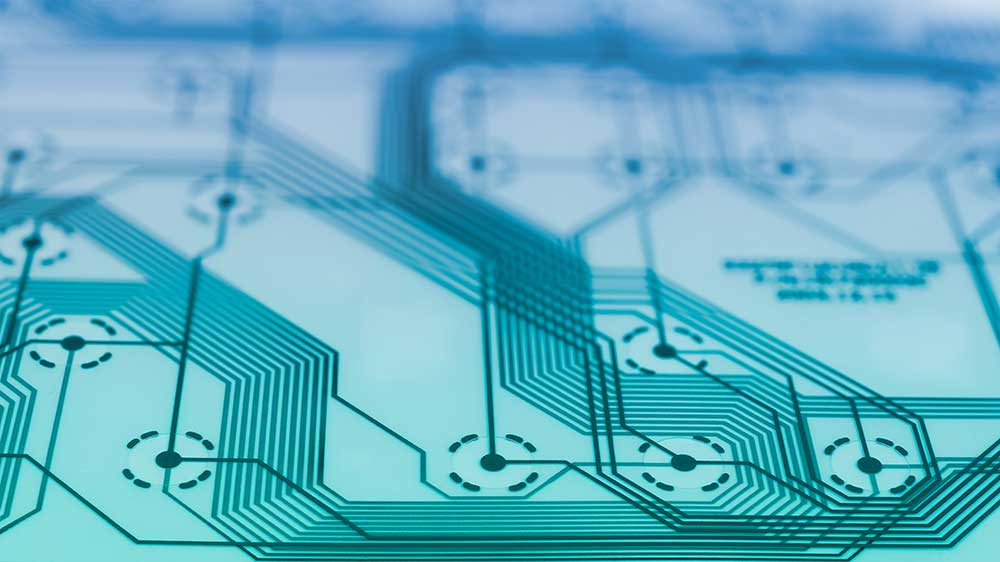

Robust & Efficient EV Charging Stations

With our Polypropylene (PP) and PETG films, we provide highly durable, weather-resistant, and aesthetically pleasing solutions for EV charging stations, ensuring they are equipped to withstand various environmental conditions.

Application Details

Specifics

In transportation, every detail counts. Whether it’s in the manufacturing of vehicle parts, cargo protection, or in the emerging field of electric vehicles, the right materials can make all the difference. Our extensive portfolio of plastic films is chosen to meet the specific demands of the transportation industry, providing tailor-made solutions for every application.

Importance of Material Selection

The selection of the right materials is crucial in the transportation industry. Factors such as weight, durability, resistance to wear, temperature, and moisture, as well as aesthetic appeal, play vital roles. Our range of plastic films meets these specific needs, offering customized solutions to enhance performance and efficiency in transportation applications.